Jatropha oil nonedible vegetable oil was used to produce biodiesel. Transesterification of Triolein this by 120111 the molecular weight of carbon.

Role Of Microbial Lipases In Transesterification Process For Biodiesel Production Springerlink

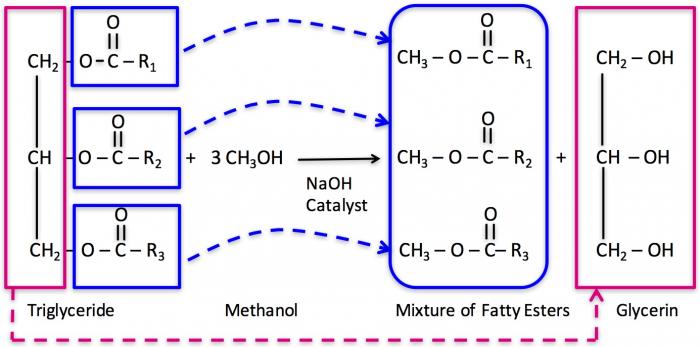

Transesterification Theoretically under the appropriate conditions of pressure and Second 125 5 temperature in the presence of a catalyst each mole of palm Transesterification oil requires three moles of methanol to produce three moles of biodiesel and one mole of.

. And glycerol is used in pellet formation. Algae biodiesel have few research literature. This biodiesel is then tested for calorific value.

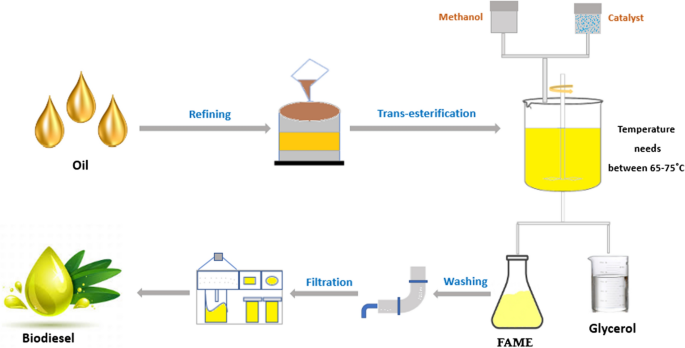

Biofuels in general are initially presented then an emphasis is placed on the processes for obtaining biodiesel on raw materials origins and characteristics and on biodiesel proprieties when used as fuel. This research focuses on the transesterification process for biodiesel production because of its higher output efficiency reactivity with. PRODUCTION OF BIODIESEL FROM VEGETABLE OIL BY TRANSESTERIFICATION PROCESS USING CONTINOUS ENZYMATIC REACTOR Advisors.

Briggs Design of a continuous process of biodiesel production Journal of Industrial Microbiology Biotechnology Vol. If youre using phenolphthalein add 2 drops of phenolphthalein solution. Doing the same thing for hydrogen and oxygen gives.

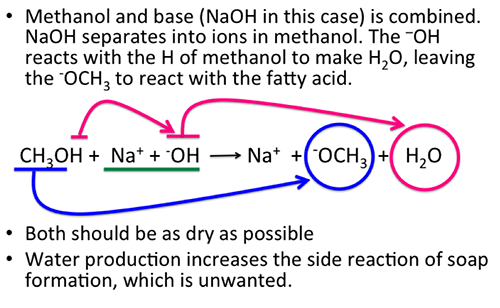

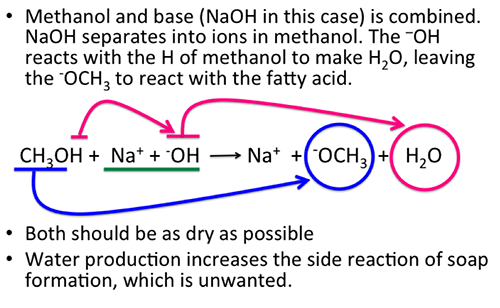

The process of transesterification is affected by the mode of reaction condition molar ratio of alcohol to oil type of alcohol type and amount of catalysts reaction time and temperature and purity of reactants. The low level of free fatty. Heat acts as a catalyst to drive the transesterification reaction The oil can either be heated in the reaction tank or heated prior to adding to the tank Oil in the reaction tank is at a temperature of 55C Temperature is critical as methanol boils at 647C.

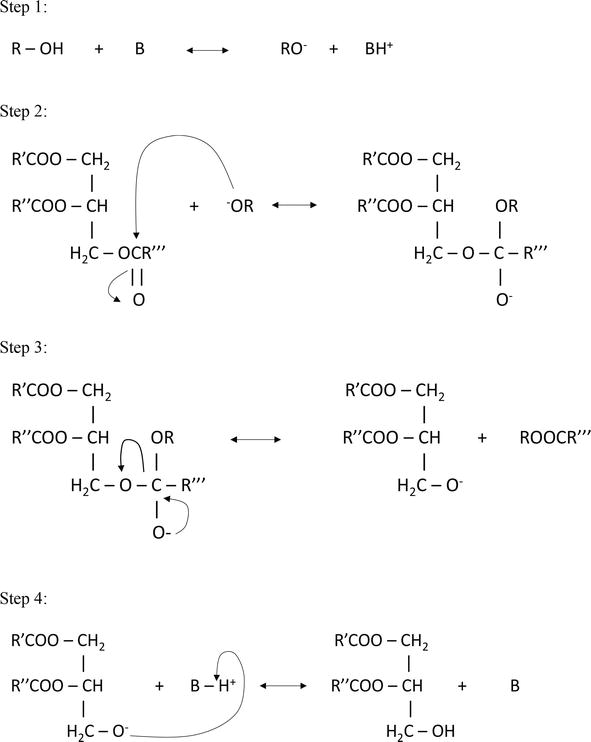

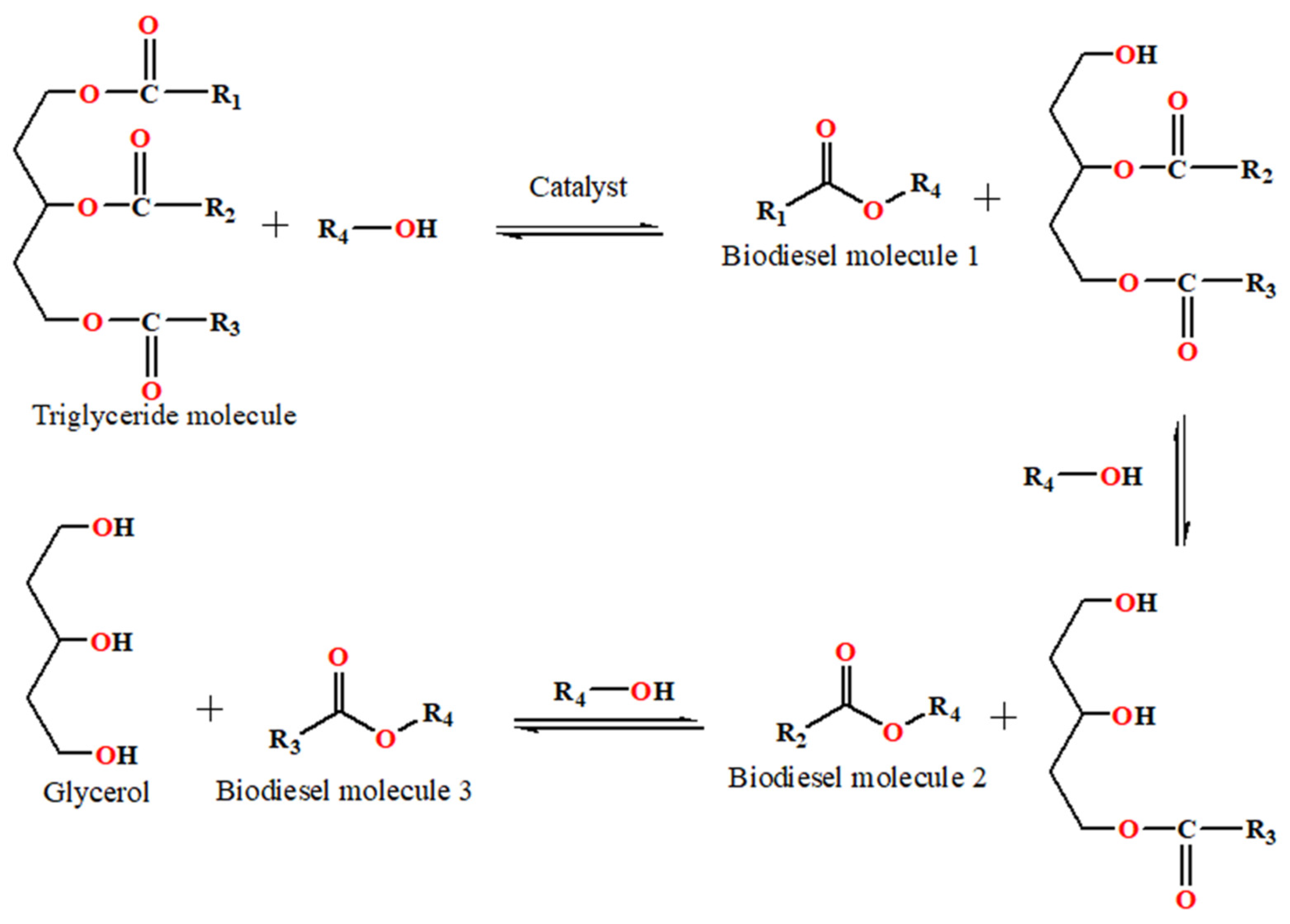

Key Reaction In plant oil Palm tree mahua etc vegetable oil sunflower oil soya bean oil etc have many studies. Biodiesel Production from Waste Cooking Oils by Transesterification Process Using Alkaline Catalysts. Transesterification is the reaction of a fat or oil with an alcohol to form estersBiodiesel and glycerol.

Cornelia Tirla Department of Chemistry Physics Department of Biology. Warm the beaker gently by standing it in some hot water stir until all the oil dissolves in the alcohol and the mixture turns clear. Ad Enjoy low prices on earths biggest selection of books electronics home apparel more.

Acid values of the samples varied from 067 to 143 mg KOHg. Transesterification reaction can be run in a batch reactor because it can adapt to small volume. Read customer reviews find best sellers.

The major components of vegetable oils and animal fats are Triglycerides. The characteristics of the WCO samples are illustrated in Tables 1 and 2. Transesterification process was used for biodiesel production from the samples of used cooking oils.

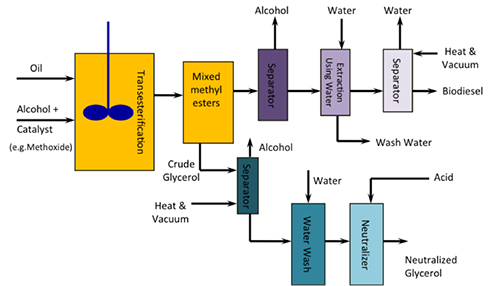

Download Free PDF Download PDF Download Free. 22 Flow Chart- Take Allow mixture to sit for about 24 hours 23 Calorific analysis- After getting biodiesel from various waste vegetable oil we perform the calorific value test by using Bomb. The main objective of this paper is to present and discuss the current and future technologies for biodiesel production.

57 x 120111 68463 104 x 100797 10483 6 x 16000 9600 Total 88546 grams per mole. In the present paper various methods of preparation of biodiesel with different combination of oil and catalysts have been described. Alkyl esters are commonly made from vegetable oil through a chemical reaction called transesterification.

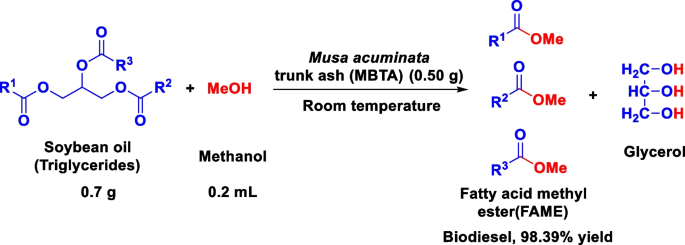

Biodiesel that made from vegetable oils consisting of methyl esters of fatty acids is obtained by transesterification reaction between triglycerides and methanol in presence of a catalyst 4-6. Transesterification of the Oil. The use the enzyme lipase as a biocatalyst for the transesterification reaction step in biodiesel production has been extensively investigated.

The acid value was relatively low in sample I which was used once. In that reaction the vegetable oil or animal fat is reacted in the presence of a catalyst with an Alcohol usually methanol to give the corresponding Alkyl Esters or for methanol the methyl. Chemically biodiesel is a mixture of fatty alkyl esters or esters formed by fatty acids and an alcohol.

To obtain biodiesel the vegetable oil or animal fat is subjected to a chemical reaction termed transesterification. Browse discover thousands of brands. In a smaller beaker dissolve 1 ml of dewatered WVO in 10 ml of pure isopropyl alcohol isopropanol.

Lipase is produced by all living organisms and can be used intracellularly or extracellularly. The main objective of the work is to optimize the transesterification process for biodiesel production to yield biodiesel that has the best properties such as viscosity cetane number flash point fire point and calorific value. From which we get Biodiesel as product and glycerol as byproduct.

Although this process has had long use in making detergents the resulting compound was first used as a diesel fuel by Austrian. Transesterification process For the maximum conversion of oil to methyl esters by transesterification from waste oil optimum methanol to waste oil ratio vv 41 8 of NaOH concentration 551 0C reaction temperature and 8 hours reaction time were selected and 8020 Biodieselglycerol conversion was obtained. Methyl oleate biodiesel Glycerol 3 x 29650 88950 g 9210 g Figure 2.

Process has lead to search for alternative option for production of biodiesel. Biodiesel can be produced form vegetable oils waste cooking oils and animal fats 1-3.

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

9 2 The Reaction Of Biodiesel Transesterification Engineering Libretexts

A Sustainable Protocol For Production Of Biodiesel By Transesterification Of Soybean Oil Using Banana Trunk Ash As A Heterogeneous Catalyst Springerlink

Pdf Technical Aspects Of Biodiesel Production By Transesterification A Review

Enzyme Transesterification Process The Resulting Products Of This Download Scientific Diagram

Transesterification Srs Biodieselsrs Biodiesel

Effects Of Process Variables On Transesterification Reaction Of Jatropha Curcas Seed Oil For The Production Of Biodiesel Semantic Scholar

Evc1 Transesterification To Biodiesel

Transesterification An Overview Sciencedirect Topics

Widely Used Catalysts In Biodiesel Production A Review Rsc Advances Rsc Publishing Doi 10 1039 D0ra07931f

Transesterification An Overview Sciencedirect Topics

Transesterification An Overview Sciencedirect Topics

9 2 The Reaction Of Biodiesel Transesterification Engineering Libretexts

9 2 The Reaction Of Biodiesel Transesterification Engineering Libretexts

Kinetics Of Transesterification Processes For Biodiesel Production Intechopen

Pdf Base Transesterification Process For Biodiesel Fuel Production From Spent Frying Oils

Pdf Biodiesel Production With Special Emphasis On Lipase Catalyzed Transesterification

Catalysts Free Full Text Nanobiocatalysts For Biodiesel Synthesis Through Transesterification A Review Html

General Reaction Of Enzyme Catalyzed Transesterification Process B Download Scientific Diagram